The Ultimate Guide: How to Wash DTF Printed T-Shirts for Longevity

You’ve invested in vibrant, durable, and highly detailed custom apparel using the cutting-edge Direct-to-Film (DTF) printing technique. DTF has quickly become an industry favorite due to its superior elasticity and ability to adhere to almost any fabric, unlike traditional direct-to-garment (DTG) or screen printing methods.

However, even the most advanced print requires careful handling. The longevity of your custom printed shirts—whether a corporate uniform or a promotional giveaway, depends almost entirely on proper laundering. This comprehensive guide details the precise steps on how to wash DTF printed t-shirts for longevity, ensuring your investment remains vibrant, crack-free, and soft for years to come.

Understanding DTF: Why It Requires Specific Care

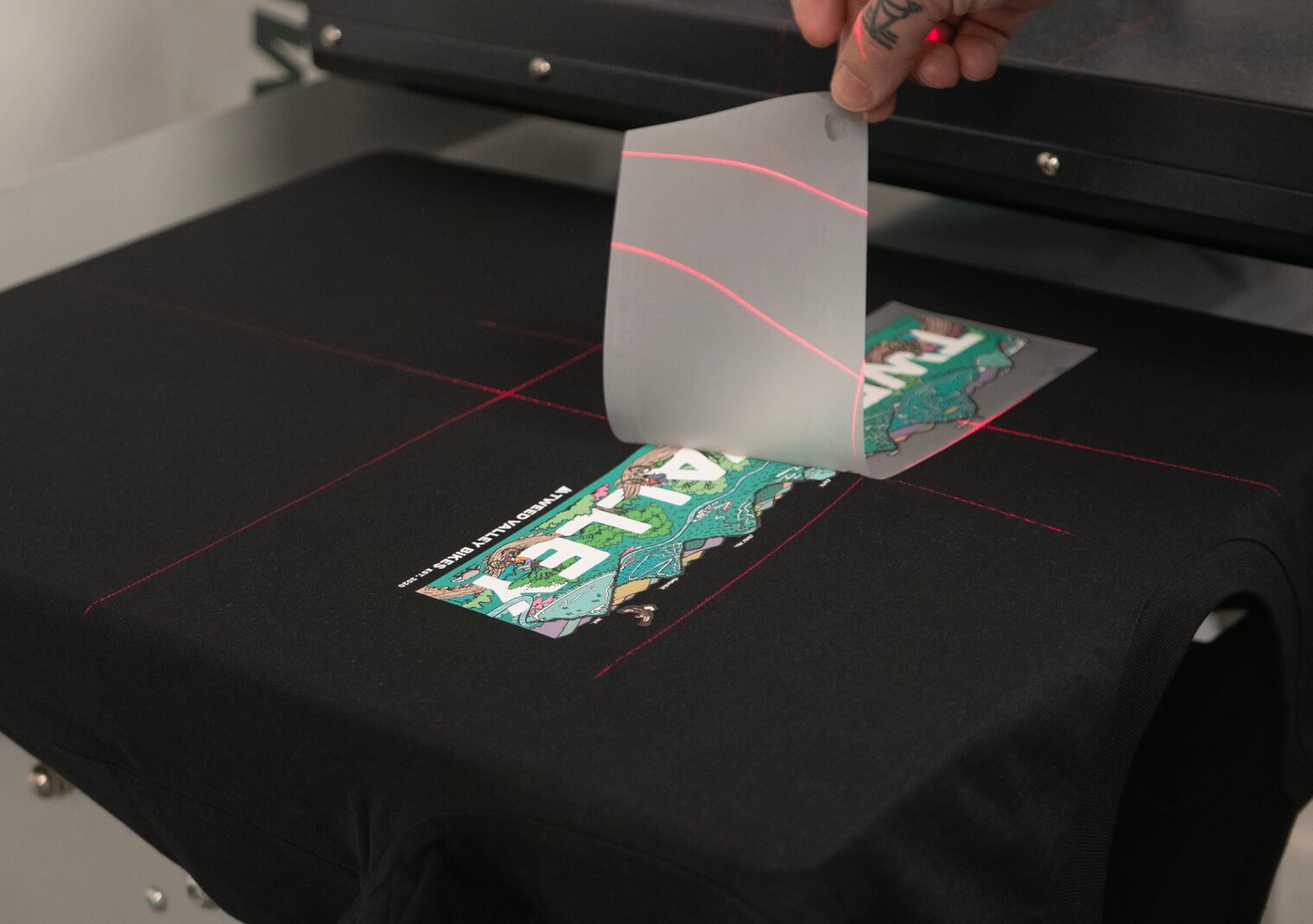

Before we discuss the washing process, it is crucial to understand the DTF technology itself. DTF is a hybrid transfer method where a specialized water-based ink is printed onto a thin film, coated with a powdered adhesive, and then cured with heat.

The DTF Advantage

- Elasticity & Feel: DTF prints are known for their exceptional stretch and relatively soft hand-feel compared to heavy vinyl or thick screen prints. This elasticity is crucial, but it relies on the adhesive bond remaining strong.

- Ink Composition: The ink is typically water-based and formulated to be flexible. Excessive heat or aggressive detergents can break down the polymer-based adhesive and the ink’s bond to the fabric fibers.

The Key Vulnerabilities

The longevity of a DTF print is primarily threatened by two factors: Heat and Friction/Abrasion. Our washing guide is specifically designed to mitigate these two risks.

Phase 1: Pre-Wash Preparation (The First 48 Hours)

The initial cure time is the single most important factor determining print durability.

1. The 48-Hour Curing Rule (Industry Standard)

Fact: All professional custom apparel manufacturers recommend a mandatory 48-hour wait period after the final heat-press application before the first wash.

- Action: Do not wash your new DTF custom printed shirts for at least two full days. This allows the DTF adhesive (the hot-melt powder) to fully cool, cure, and bond completely with the garment fibers, achieving maximum tensile strength. Washing prematurely risks immediate peeling or cracking.

2. Turning the Garment Inside-Out

The single most effective step in caring for custom printed shirts is to turn the shirt inside-out before every wash.

- Principle: This protects the delicate printed surface from the physical abrasion caused by the washing drum walls, zippers, buttons, and other garments in the load. The friction damages the ink layer over time, leading to premature fading and micro-cracking.

Phase 2: The Washing Cycle (How to Wash DTF Printed T-Shirts for Longevity)

The washing cycle presents the highest risk of heat damage, abrasion, and chemical breakdown of the adhesive.

3. Use Cold Water Only (The Golden Rule)

Primary Directive: Always wash DTF printed garments in cold water (below 30°C / 86°F).

- Why Cold Water? Heat is the natural enemy of the polymer adhesive used in DTF. Hot water softens and gradually degrades the adhesive bond, making the print susceptible to peeling, fading, and lifting during the agitation of the wash cycle. Washing in cold water maintains the integrity of this crucial bond.

4. Choose the Right Cycle Setting (Gentle is Non-Negotiable)

- Setting: Use the machine’s “Gentle” or “Delicates” cycle.

- Principle: The gentle cycle minimizes the speed and force of the wash barrel’s agitation. Reduced mechanical action equals reduced friction and stress on the printed area. High-speed spin cycles should also be avoided, as the centrifugal force can stretch and weaken the printed design.

5. Detergent Selection: Avoid Harsh Chemicals

The chemicals in your laundry products can dissolve or damage the DTF pigments and adhesive over time, that’s why it is important to now how to wash DTF printed t-shirts safely.

- Avoid: Bleach (chlorine or oxygen-based), Fabric Softeners, and harsh Stain Removers.

- Why: Fabric softeners leave a chemical coating on the fabric that can interfere with the print’s flexibility and appearance. Bleach and powerful stain removers will immediately strip the color pigments, leading to dramatic fading and discoloration.

- Recommendation: Use a mild, colour-safe detergent in liquid form. Liquid detergent dissolves better in cold water than powder, reducing the chance of detergent residue getting trapped in the fabric or print.

6. Wash Separately or with Similar Fabrics

- Avoid: Mixing DTF shirts with heavy, abrasive fabrics like denim, towels, or garments with heavy zippers/studs.

- Reason: The high surface roughness of denim and towels acts like sandpaper against the print during agitation, accelerating the wear and tear of the print layer. Wash DTF apparel only with other lightweight custom clothing and synthetics.

Phase 3: Drying and Finishing (Mitigating Heat Risk)

This is the second major area where heat can ruin a DTF print—often more quickly and irreversibly than the wash cycle itself.

7. Hang Dry or Lay Flat (The Most Critical Step in how to wash dtf printed t-shirts)

Primary Directive: Never put DTF printed T-shirts in a high-heat tumble dryer.

- Action: Tumble drying is the fastest way to destroy the adhesive and print. The combination of high heat and continuous tumbling/friction will cause the print to crack, peel, and wrinkle almost immediately.

- The Only Safe Method: Air-dry the garment. Either hang it on a rack or a clothesline, or lay it flat. This preserves the print’s flexibility and softness.

8. Ironing Rules: Never Direct Heat

Ironing can melt the DTF adhesive and print layer instantly.

- Action: If ironing is necessary to remove wrinkles, always turn the shirt inside-out and use the lowest temperature setting possible (synthetic or nylon setting). Never apply the hot iron directly to the printed side. Iron around the design, or place a thin cloth (like a tea towel or parchment paper) over the design before gentle, indirect pressing.

Industry Best Practices and Durability Expectations

While DTF is a highly durable printing method, its longevity is not infinite, and care instructions are backed by textile chemistry and industry testing standards.

Research and Testing on DTF Wash Fastness

Industry wash-testing protocols, such as those governed by the American Association of Textile Chemists and Colorists (AATCC), confirm that DTF prints can withstand 40–50 home wash cycles when the care instructions are strictly followed.

- Fading Rate: Under optimal washing conditions (cold water, gentle cycle), minimal color loss (5%) should occur over the first 25 washes. Beyond this, minor, uniform fading is to be expected, which is typical for all water-based textile inks.

- Key Insight: Prints that fail prematurely (peeling after 5-10 washes) almost always point to one of two issues: excessive heat exposure (in the dryer) or improper pre-press curing during the manufacturing process.

Longevity Comparison

| Printing Method | Primary Vulnerability | Wash Best Practice | Estimated Longevity (Good Care) |

|---|---|---|---|

| Screen Printing (Plastisol) | Stiffness/Cracking | Warm water acceptable, but avoid high heat drying. | Very High (Often outlasts the garment) |

| DTG (Direct-to-Garment) | Washing Friction/Abrasion | Cold water, delicate cycle, air dry. | Medium (Can fade over time) |

| DTF (Direct-to-Film) | Heat (Melts adhesive) | Cold water, inside-out, air dry. | High (Excellent resistance to cracking) |

The clear takeaway is that DTF requires cold water and air-drying to leverage its superior flexibility. This final comparison reinforces why learning how to wash DTF printed t-shirts for longevity is different from caring for other apparel.

Quick Reference Checklist: How to wash DTF printed T-Shirts

To keep your custom printed shirts looking new, tape this checklist inside your laundry room:

| Care Instruction | Why It Matters | Status |

|---|---|---|

| Wait 48 Hours | Allows the polymer adhesive to fully cure. | MANDATORY |

| Turn Inside-Out | Prevents friction damage during the wash cycle. | MANDATORY |

| Use Cold Water | Prevents the adhesive from softening and peeling. | MANDATORY |

| Use Gentle Cycle | Minimizes agitation and stretching of the print. | REQUIRED |

| Use Mild Detergent | Avoids chemical breakdown from bleach/softeners. | REQUIRED |

| Air Dry | Eliminates the high-heat, high-friction damage from dryers. | MANDATORY |

| Never Iron Direct | Direct heat will immediately melt the print. | MANDATORY |

By following these specific steps, you are not just washing a shirt; you are actively preserving the cutting-edge technology that created your design. Proper care is the final and most important step in enjoying your vibrant DTF custom clothing for as long as possible.