Cotton vs. Polyester: Choosing the Right Fabric for Custom T-Shirts Design

The foundation of a great custom T-shirt isn’t the design; it’s the fabric. Before you even finalize your logo or choose your colours, you need to answer a fundamental question: What is the right fabric for custom T-shirts?

This decision impacts everything: how the shirt feels; how the hand feel, how long the print lasts, how the shirt drapes on the body, and, critically, which printing technology you can use. Choosing between natural fibers like cotton and synthetic polymers like polyester—or a combination of the two is the single most important decision for your final product.

This ultimate guide breaks down the science, the feel, and the printing implications of each fabric type. By the end, you’ll know exactly how to select the right fabric for custom T-shirts that perfectly matches your design, budget, and intended use.

The All-Natural Contender: Cotton

Cotton remains the undisputed champion of the apparel world. A staple crop that has defined comfort for centuries, cotton is a natural cellulose fiber known for its incredible softness and breathability.

The Science of Comfort and Absorbency

Cotton is a highly hydrophilic fiber, meaning it loves water. Its unique structure, characterized by tiny hollow spaces, allows it to absorb significant amounts of moisture (up to 27 times its weight) and air. This property is known as moisture regain.

- Softness: The fiber’s structure naturally gives it a soft, non-abrasive texture, making it ideal for daily wear and sensitive skin.

- Breathability: Its ability to absorb moisture and allow air to pass through keeps the wearer cool in warm environments.

- Insulation: While breathable, the air trapped within its fibers provides enough insulation to be comfortable in transitional weather.

Cotton Grades and Quality

Not all cotton is equal. The quality of the finished garment depends heavily on the length of the fibers (staple length) and the yarn processing method:

| Cotton Type | Staple Length | Hand-Feel & Quality | Best Use |

| Standard Cotton | Short | Stiffer, heavier, more prone to pilling. | Bulk promotional wear, heavier hoodies. |

| Ring-Spun Cotton | Medium-to-Long | Softer, smoother, higher thread count feel. | Mid-to-high quality fashion tees, retail wear. |

| Combed/Pima/Supima | Longest | Extremely soft, durable, minimal pilling. | Premium fashion, garments requiring exceptional longevity. |

Printing on 100% Cotton

Cotton is the most versatile canvas for printing, but it particularly excels with techniques that utilize water-based inks:

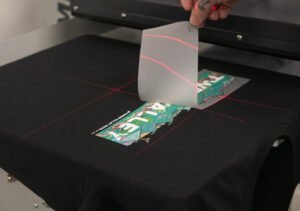

- Direct-to-Garment (DTG): DTG printing is specifically designed for cotton. The water-based ink binds directly with the natural cellulose fibers, resulting in a soft, non-plastic-like print (a superior ‘hand-feel’).

- Screen Printing: This classic method adheres well to cotton, particularly with plastisol or water-based inks. Cotton’s rougher surface holds the ink securely.

Key Considerations for 100% Cotton

| Pros | Cons |

| Exceptional softness and comfort. | Prone to shrinkage (up to 5% is standard, even with pre-shrunk cotton). |

| Naturally hypoallergenic and breathable. | Holds moisture, making it heavy and slow to dry (bad for intense sports). |

| Excellent canvas for high-detail DTG prints. | Prone to wrinkling and requires more ironing/steaming. |

The Synthetic Performer: Polyester

Polyester is a manufactured synthetic fiber (a plastic polymer). When cotton is the casual, everyday champion, polyester is the performance workhorse.

The Science of Durability and Wicking

Unlike cotton, polyester is hydrophobic—it repels water. This fundamental difference drives all its core properties:

- Durability and Resilience: Polyester fibers are chemically robust, offering excellent resistance to wear and tear, stretching, shrinking, and chemical damage. It holds its shape extremely well, resisting wrinkles.

- Moisture-Wicking: Because it repels water, instead of absorbing sweat, polyester transports it along the fiber surface to the outside of the fabric, where it evaporates quickly. This is crucial for activewear.

- Color Fastness: The dye bonds tightly to the synthetic polymer, making the colours exceptionally vibrant and fade-resistant, even after extensive washing.

Printing on 100% Polyester

The hydrophobic nature of polyester dictates a vastly different, but highly effective, printing technique.

- Dye Sublimation: This is the ultimate method for polyester. Sublimation uses heat to turn solid ink directly into a gas, which then chemically bonds with the polyester polymers. The result is a vibrant, full-color design that is literally part of the fabric.

- Industry Standard Fact: Dye sublimation is only effective on fabrics that are at least 65% polyester or higher. It yields an incredibly soft hand-feel because the ink is fully integrated, not sitting on top of the fabric.

- Screen Printing/DTG on Polyester: While possible, it requires special water-resistant inks, pretreatment layers, and often results in a less vibrant print and a heavier, less comfortable feel.

Key Considerations for 100% Polyester

| Pros | Cons |

| Fast drying and excellent moisture-wicking. | Low breathability (can feel clammy in very hot, humid conditions). |

| Highly durable, wrinkle-resistant, and maintains shape. | Susceptible to holding onto body odors (requires special washing agents). |

| Perfect for Dye Sublimation (vibrant, permanent colours). | Can melt or scorch under high heat (requires careful ironing and drying). |

The Strategic Choice: Cotton vs Polyester Blends

Most modern custom apparel, particularly for retail and fashion, utilizes cotton vs polyester blends. These blends are designed to mitigate the weaknesses of the individual fibers while combining their strengths.

The most common blend is the 50/50 blend (50% Cotton, 50% Polyester), but the Tri-blend has revolutionized the garment industry.

Tri-Blends: The Modern Fabric Standard

A Tri-blend typically consists of three fibers:

- Cotton: For softness and breathability.

- Polyester: For wrinkle resistance, moisture-wicking, and durability.

- Rayon (or sometimes Modal): A semi-synthetic fiber derived from purified cellulose. It provides exceptional drape, elasticity, and a luxurious silky ‘hand-feel’.

The result of using these three fibers is a fabric that is softer, drapes better, and is less prone to shrinking and wrinkling than 100% cotton, while still retaining some moisture-wicking properties better than pure polyester. When choosing the right fabric for custom T-shirts used in modern retail, the Tri-blend is often the premium choice.

Printing on Blends

The printing method for cotton vs polyester blends depends heavily on the ratio:

- High Cotton Content (60% Cotton / 40% Poly): You should generally use DTG (Direct-to-Garment). The high cotton count ensures the water-based ink has enough natural fiber to bind to, while the polyester adds structural stability to the print.

- High Polyester Content (60% Poly / 40% Cotton): You can use Dye Sublimation for lighter-colored shirts, achieving good color, but the final result will be slightly less vibrant than on 100% poly.

Choosing the Right Fabric for Custom T-Shirts Based on Purpose

To select the right fabric for custom T-shirts, you must match the fabric’s properties to the intended application. This is the core principle of advanced custom apparel design.

| Intended Purpose | Primary Fabric Goal | Recommended Fabric | Key Printing Method |

| Athletics / Gym Wear | Maximum Wicking, Fast Drying, Durability | 100% Polyester (Performance Knit) | Dye Sublimation or Heat Transfer Vinyl |

| Fashion / Retail | Soft Hand-Feel, Drape, Comfort | Tri-Blends (Cotton/Poly/Rayon) | Screen Printing (Water-based inks) or DTG |

| Promotional / Events | Cost-Effectiveness, Standard Comfort | Standard 100% Cotton or 50/50 Poly-Cotton | Screen Printing (Plastisol) |

| Luxury / Brand Merch | Premium Feel, Longevity | Ring-Spun Combed Cotton or Premium Tri-Blend | DTG or High-Density Screen Print |

Fabric Weight: GSM and Durability

Fabric weight is measured in Grams per Square Meter (GSM). This is a critical factor when determining the right fabric for custom T-shirts for your needs:

- Lightweight (120-150 GSM): Great for breathable summer wear and layering. Often found in premium Tri-blends.

- Mid-Weight (160-180 GSM): The industry standard for retail T-shirts. Offers durability, good hand-feel, and excellent print surface. Most 100% Ring-Spun cotton falls here.

- Heavyweight (190+ GSM): Ideal for durability, workwear, or cold-weather hoodies.

The Economic Factor

While polyester is often cheaper to manufacture than premium cotton, the initial price difference often disappears when factoring in the cost of high-tech printing:

- DTG (Cotton): Can have a higher per-item cost due to pretreatment and ink consumption, but allows for low minimum order quantities (MOQ).

- Sublimation (Polyester): Requires a higher minimum quantity for cost efficiency but offers a permanent, vibrant, all-over print that is extremely durable.

Sustainability and Longevity

In modern custom apparel, the right fabric for custom T-shirts decision also involves ethical and environmental considerations:

- Cotton (Natural): While biodegradable, conventional cotton production is extremely water-intensive. Look for Organic Cotton to minimize environmental impact and water usage.

- Polyester (Synthetic): Durable and recyclable, but not biodegradable. However, its longevity means garments last longer, reducing turnover. Look for Recycled Polyester (rPET) to utilize waste plastic.

Industry Fact: Research shows that the greatest environmental impact of a garment comes from the use phase (washing and drying). Because polyester dries quickly and resists wrinkles, it can reduce energy consumption over its lifetime compared to cotton, which requires high heat drying and ironing.

Final Verdict: Which Fabric is Right for You?

The true answer to selecting the right fabric for custom T-shirts is that it depends entirely on the experience you want to deliver.

- If your design is for everyday comfort, fashion, or complex, photo-realistic artwork with a soft feel, choose a high-quality Ring-Spun Cotton or a Tri-blend. The natural fibers will give you the best drape and the most effective surface for DTG printing.

- If your design is for a sports team, a summer event, or requires maximum durability and all-over, permanent color, choose 100% Polyester (or a high-poly blend). You must utilize Dye Sublimation for this purpose to ensure the longevity and vibrancy you need.

By aligning your fabric choice with the final use and the correct printing technology, you ensure your custom apparel not only looks incredible but performs perfectly for years to come.